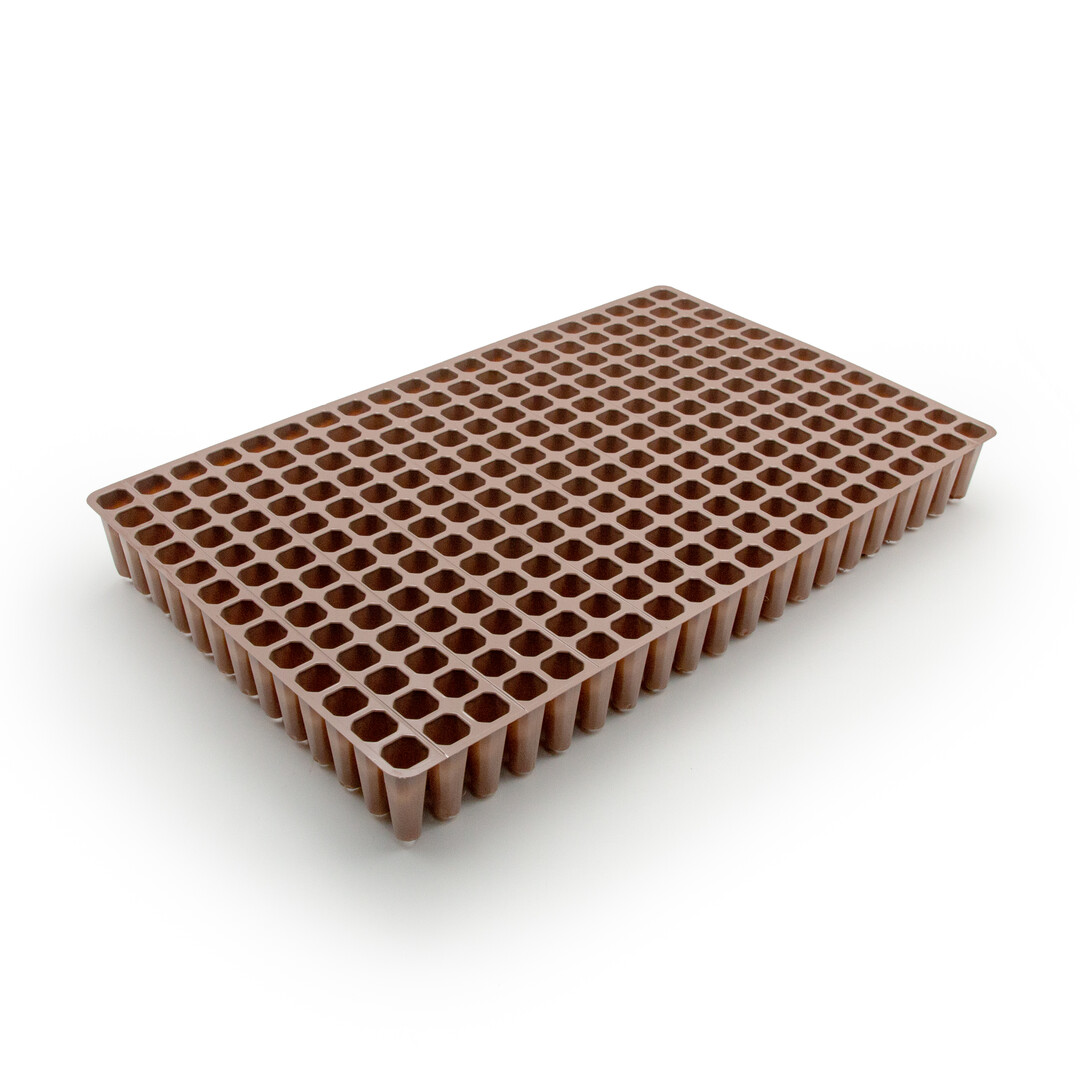

Propagation tray with a reduced environmental impact

Developed for industrial tomato growers, it is designed for coating other propagation tray types. This product is the latest innovation in a complete range of professional solutions for vegetable and flower nurseries developed using recycled PET and characterised by the unique grey colour and performance that matches that of equivalent polystyrene products.

- Published on

After taking part in IPM, the reference international trade fair for horticulture held last January in Essen, Germany, ILIP, a leading Italian packaging solutions provider, has unveiled its latest innovation, the R-PET propagation tray, at the MyPlant & Garden exhibition in Milan, held from 22nd to 24th February 2023. Developed for industrial tomato growers, the tray is designed for coating other propagation tray types and is made from recycled PET, resulting in a reduced environmental impact.

ILIP's range of professional solutions for vegetable and flower nurseries, including propagation trays, carriers with trays, transport and cultivation potholders, and pots with diameters of 10 and 14 cm, are all completely recyclable and made from PS and R-PET, resulting from the post-consumption recycling of PET food packaging and R-PET milk bottles. The grey-coloured secondary raw material used in its products is entirely traceable as it comes from a chain of recycling and extrusion of plastic that is controlled completely by the ILPA Group of which ILIP is a member, one of the few concrete cases in Europe of circular economy in the packaging industry.

New this year, ILIP will be launching its propagation tray made from R-PET only, to be combined with the XPS (extruded, expanded polystyrene) propagation trays. This reduces the use of plastic materials and accordingly the environmental impact of the product itself as the part in R-PET, after its cycle of use, is eliminated, whilst the XPS component (which, as it is below the other, has not been contaminated) can be reused for multiple years. This solution has been developed for industrial tomato growers and offers 260 or 280 holes with a volume, respectively, of 14 and 15.4 cc